Evaluating your Oil Well Intervention

MSDS

Oil Well Info Form

Click here to use Electronic Form

Complete this form for each candidate oil well.

Ideal will be to have 5 candidate wells for each treatment.

Evaluation of the candidate wells will allows us to provide project engineering and estimate post treatment success.

Logistics

Biotech Processing Supply works with agents and Oil Field operators to arrange project

evaluation, promotion, Sale, Distribution and Shipment of GreenZyme® Technology

Most of our orders ship in 20’ or 40’ containers for FOB or CIF international shipping,

flat bed trucks for distribution in the Continental USA to client or Forwarding agent.

Container & Packing

•

55gal drum + wood pallet (4 drums per pallet)

•

220gal IBC Container with integrated pallet

Cargo is inspected before it boards the shipping container:

•

IBC or Drum & Pallet Integrity.

•

Sealed Top Cap with additional tamper evident seals

•

Steel Strapping for drums, steel cage for IBC protection

•

Secured Bottom IBC Valve with tamper evident seal

Quality Control & Inventory Tracking to each individual country:

•

Proper Import - Export labeling is attached to each Drum or IBC.

•

Each Drum or IBC of GreenZyme® carries a Unique Numbered Security

Identification Label specific to each Country or Territory

Certificate of Shipping, Transport & Free Trade Agreements

•

Shipping Container Number

•

Quality Control Identification Label Numbers

•

Shipping Container Metallic Seal Number

•

Project Name and Destination

GreenZyme® Single Well Booster Treatment

Treatments are usually very simple and can be completed in a

single day. Most Huff n Puff treatments to date have used 220 to

330 gallons of GreenZyme® diluted to concentrations between 2

to 10% solution in a mixing tank and then pumped inside the well

by the casing side. Additional formation water is injected to clear

the casing length and displace the solution into the formation.

Once the the pumping is completed, the well is closed for 3-7

days to give the enzyme time to perform its Biological Function

before resuming production.

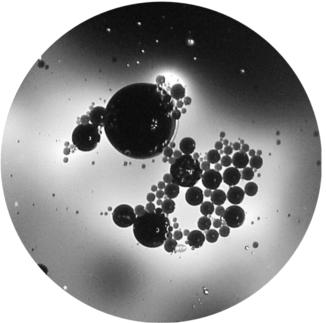

GreenZyme® is used to unclog near well-bore from Paraffin

build-up while mobilizing pockets of trapped oil in the reservoir.

In many cases formation damage is also removed.

Enzyme technology reduces the interfacial tension of the rock

surface using formation water to improve permeability and

mobility of the oil.

GreenZyme® EOR for Waterfloods

The GreenZyme® Enhanced Oil Recovery fluid can be slugged

or injected sporadically in a waterflooding to sweep the formation

and improve sweep efficiency.

Pumping GreenZyme® into injector wells is a simple procedure.

Given the limits that currently exist for recovery technologies,

treatment with GreenZyme® solution is an exceptional way to

achieve improved oil recovery - including at lower API gravity oil.

Biotech Processing Supply has industry experience in many other

uses for GreenZyme®:

Heavy Oil

Steam Cycle Precursor

Water Alternating Gas Injection (WAG)

Remediation

Storage Tank Sludge Clean-up

Remediation of contaminated soils and water, produced water

Biological enzyme is reusable for continuous cycles

Vertical & Horizontal wells

On Shore & Off Shore

Biotech Processing Supply

sales@btprocessing.com / 214 884 5554

NAVIGATION

SOCIAL

Contact

Biotech Processing Supply

Dallas, TX

Houston, Tx

Singapore

sales@btprocessing.com

214 884 5554

sales@btprocessing.com / 214 884 5554

Evaluating your Oil Well Intervention

MSDS

Oil Well Info Form

Click here to use Electronic Form

Complete this form for each candidate oil well.

Ideal will be to have 5 candidate wells for each treatment.

Evaluation of the candidate wells will allows us to provide project engineering

and estimate post treatment success.

Logistics

Biotech Processing Supply works with agents and Oil

Field operators to arrange project evaluation,

promotion, Sale, Distribution and Shipment of

GreenZyme® Technology

Most of our orders ship in 20’ or 40’ containers for FOB

or CIF international shipping, flat bed trucks for

distribution in the Continental USA to client or

Forwarding agent.

Container & Packing

•

55gal drum + wood pallet (4 drums per pallet)

•

220gal IBC Container with integrated pallet

Cargo is inspected before it boards the shipping

container:

•

IBC or Drum & Pallet Integrity.

•

Sealed Top Cap with additional tamper evident

seals

•

Steel Strapping for drums, steel cage for IBC

protection

•

Secured Bottom IBC Valve with tamper evident

seal

Quality Control & Inventory Tracking to each individual

country:

•

Proper Import - Export labeling is attached to

each Drum or IBC.

•

Each Drum or IBC of GreenZyme® carries a

Unique Numbered Security Identification Label

specific to each Country or Territory

Certificate of Shipping, Transport & Free Trade

Agreements

•

Shipping Container Number

•

Quality Control Identification Label Numbers

•

Shipping Container Metallic Seal Number

•

Project Name and Destination

GreenZyme® Single Well Booster Treatment

Treatments are usually very simple and can be

completed in a single day. Most Huff n Puff

treatments to date have used 220 to 330 gallons of

GreenZyme® diluted to concentrations between 2 to

10% solution in a mixing tank and then pumped inside

the well by the casing side. Additional formation water

is injected to clear the casing length and displace the

solution into the formation.

Once the the pumping is completed, the well is closed

for 3-7 days to give the enzyme time to perform its

Biological Function before resuming production.

GreenZyme® is used to unclog near well-bore from

Paraffin build-up while mobilizing pockets of trapped

oil in the reservoir. In many cases formation damage is

also removed.

Enzyme technology reduces the interfacial tension of

the rock surface using formation water to improve

permeability and mobility of the oil.

GreenZyme® EOR for Waterfloods

The GreenZyme® Enhanced Oil Recovery fluid can

be slugged or injected sporadically in a waterflooding

to sweep the formation and improve sweep efficiency.

Pumping GreenZyme® into injector wells is a simple

procedure. Given the limits that currently exist for

recovery technologies, treatment with GreenZyme®

solution is an exceptional way to achieve improved oil

recovery - including at lower API gravity oil.

Biotech Processing Supply has industry experience in

many other uses for GreenZyme®:

Heavy Oil

Steam Cycle Precursor

Water Alternating Gas Injection (WAG)

Remediation

Storage Tank Sludge Clean-up

Remediation of contaminated soils and water,

produced water

Biological enzyme is reusable for continuous cycles

Vertical & Horizontal wells

On Shore & Off Shore